Leeham News and Analysis

There's more to real news than a news release.

Could an NMA be made good enough, Part 2?

By Bjorn Fehrm

Subscription Required

Introduction

April 3, 2017, © Leeham Co.: In the first part of our investigation on how good an NMA can be, we explored low weight and drag fuselage design. We will now continue with the design consequences for the fuselage construction and the cabin.

What drives whether one goes for an Aluminum or CFRP (Carbon Fiber Reinforced Polymer) fuselage?

Figure 1. The NMA takes more and more the shape of a 767 replacement (A United 767-200 pictured). Source: United.

What will be the typical dimensions for an NMA fuselage and what will be passenger capacities?

Summary:

- An elliptical fuselage will force a CFRP design.

- The fuselage door configuration will be critical for cabin capacity and flexibility.

Bjorn’s Corner: Aircraft engine maintenance, Part 5

March 31, 2017, ©. Leeham Co: In the last Corner, we showed flight hour graphs for wide-body engines. Now we will deduce the market for engine overhauls from these graphs.

It will show which engines are still in engine manufacturer care, in their main maintenance cycle and in the sun-set phase.

The phase the engine is in and its future flight hour development will decide the attractiveness of the engine for overhaul organizations. Read more

Bjorn’s Corner: Aircraft engine maintenance, Part 4

March 24, 2017, ©. Leeham Co: After covering the maintenance market for single-aisle engines, time has come for the engines used on wide-body aircraft. The engine maintenance for a wide-body engine is a bit different to the single-aisle engine. The difference is caused by the longer flight times for the wide-bodies. This makes the flight time wear a more dominant maintenance driver than it is for the single-aisle engines.

The changes in overhaul work caused by the difference in flight profiles and the lower number of engines in the market (compared to the single aisles) will affect how the overhaul market is structured and who are the dominant players.

Could an NMA be made good enough?

By Bjorn Fehrm

Subscription Required

Introduction

March 23, 2017, © Leeham Co.: After showing there exists an NMA (New Midrange Aircraft) gap, the next question follows: Can an aircraft be made for the segment that can carve out a big enough slice to make it a worthwhile effort?

It’s a tough question. Any new aircraft will cost at least $10bn to develop for the airframe alone. To this one shall add the engine development. There exists no suitable engine for such an aircraft. To motivate the investments, the aircraft has to bring a substantial performance improvement compared to existing aircraft. Can it?

Figure 1. The NMA takes more and more the shape of a 767 replacement (A United 767-200). Source: United

We go through the key areas that can bring improvements and check if enough progress can is made until an NMA entry into service in 2024 or 2025.

Summary:

- Existing aircraft are either too little or too much aircraft to fill an NMA role.

- By careful design choices, especially for the fuselage, a new aircraft can achieve the required performance.

easyJet, the Ryanair follower

By Bjorn Fehrm

-March 22, 2017, ©. Leeham Co: easyJet started 10 years after Ryanair, using the same Southwest Airlines derived Low Cost Carrier (LCC) business model.

easyJet has been expanding at the pace of Ryanair over the years, trailing the European LCC pioneer by around 20% to 30% of passengers carried each year.

For the last fiscal year ending 30 September 2016, easyJet carried 73 million passengers between 30 countries, flying 820 different routes.

Bjorn’s Corner: Aircraft engine maintenance, Part 3

March 17, 2017, ©. Leeham Co: In the last Corner, we showed graphs of the yearly flight hours for engines on single-aisle aircraft. Now we will deduce the market for engine overhauls from these graphs.

These will show which engines generate a maintenance volume that is interesting for engine overhaul companies and which engines are niche.

Based on the market size, we will then go through how an engine is maintained when new, mature and at end-of-life.

Boeing 737 MAX 10 analyzed

By Bjorn Fehrm

Note: Boeing’s “soft launch” of the 737-10 MAX at the ISTAT conference in San Diego a week ago met with some sharp criticism by lessors and some others. Within hours, Boeing scheduled a conference call for reporters the next day to defend and promote the airplane. LNC closely tracked the development of the MAX 10 and its competivitive position vis-a-vis the Airbus A321neo. Here is our first detailed, public analysis of the MAX 10.–Editor.

Subscription Required

Introduction

March 12, 2017, © Leeham Co.: Boeing has taken the wraps of the 737 MAX 10. Its overall configuration has long been known to LNC, but we now have more data and performance claims that we can analyze.

Boeing claims the MAX 10 flies farther, cheaper and with just about the same numbers of passengers as the class-leading Airbus A321neo. We now have enough data to analyze if this is true. We put the data in our performance model and here is the result.

We now have enough data to analyze if this is true. We put the data in our performance model and here is the result.

Summary:

- Boeing’s claims on a basic level seem OK. The seating is close to the A321neo.

- On a higher level it starts to stutter. Our model can’t agree on the 5% better economics.

Read more

Bjorn’s Corner: Aircraft engines maintenance, Part 2

March 10, 2017, ©. Leeham Co: Last week we started the series how airline turbofans are maintained. We described the typical work scopes and what the intervals were for different single-aisle engines.

Before we can describe the engine maintenance market we must get a feel for the market size for different engine types.

We will start with understanding the single-aisle engine maintenance market. Read more

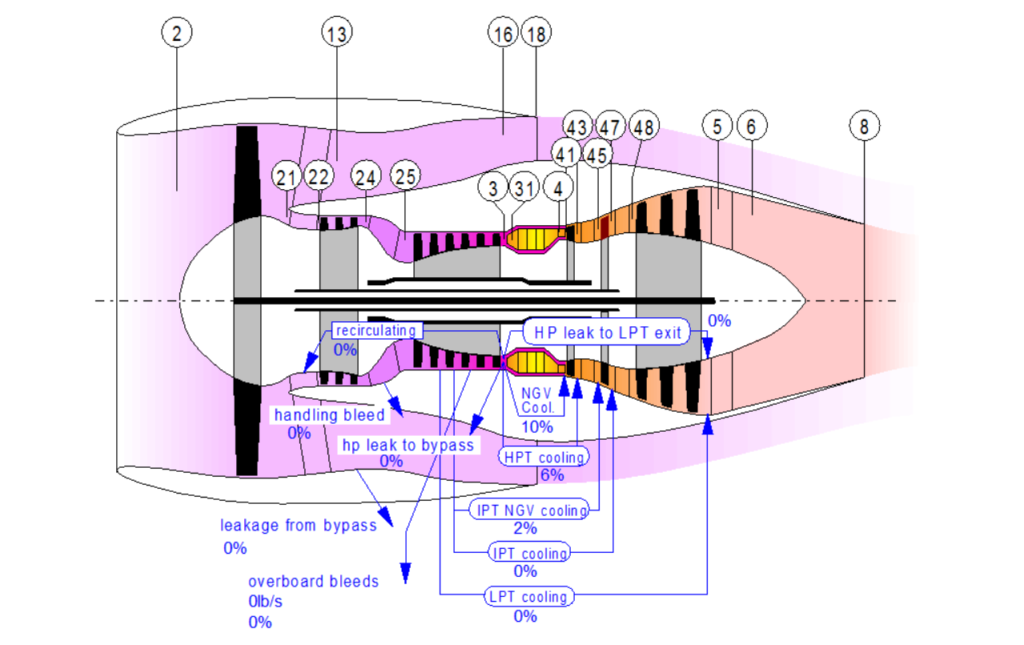

Bjorn’s Corner: Aircraft engine maintenance, Part 1

March 3, 2017, ©. Leeham Co: We will now go through how airline turbofans are maintained. First, we will describe the typical work which is performed, then look into the markets for engine maintenance.

In the markets for engine maintenance, we will look at who the players are, how they are related to the engine OEMs and why the market dynamics are very different between engines for single-aisle aircraft and wide-bodies.