Leeham News and Analysis

There's more to real news than a news release.

Bjorn’s Corner: The challenges of airliner development. Part 29. Finishing Flight tests

November 12, 2021, ©. Leeham News: Last week, we looked at our role in creating comprehensive crew training so the aircraft can be safely operated during its lifetime.

With maintenance and crew training docs and curriculums well underway we can return to our Flight tests and describe how we finish up the testing and get our Type Certificate.

Bjorn’s Corner: The challenges of airliner development. Part 28. Crew training

November 5, 2021, ©. Leeham News: Last week, we looked at our role in creating a competent maintenance activity so our aircraft can be kept airworthy throughout its operational life. The other important part of operational safety is crew training.

We learned that these two parts, keeping the aircraft airworthy with its maintenance and providing adequate training and information to the crews operating the airplane, have a major influence on flight safety. In fact, FAA has found that these parts have a larger influence on flight safety than the aircraft certification regulations.

We, as the OEM, must therefore develop the documentation, curriculum, and training tools so that crews working in the aircraft can fly it safely. This encompasses not only initial training but a continued refresh and check training throughout the crew’s life with the aircraft.

Bjorn’s Corner: The challenges of airliner development. Part 26. Maintenance planning

October 22, 2021, ©. Leeham News: Last week, we looked into Continued Operational Safety and there specifically Safety Monitoring and Reporting. Now we look at the role Instructions for Continued Airworthiness (ICAs) play in preventing the air safety issues we talked about last week.

An important part of the Instructions for Continued Airworthiness, ICA, is how to maintain the aircraft in a continued airworthy state during its operational life. The aircraft is airworthy when it rolls out of the factory but it needs to keep this condition for its 25 years or longer productive life. How this is done is contained in the maintenance documents, but there is more to it than just producing a maintenance manual.

Bjorn’s Corner: The challenges of airliner development. Part 25. Safety monitoring and reporting

October 15, 2021, ©. Leeham News: Last week, we introduced the activities around Continued Airworthiness that we have to do during development and flight testing of our aircraft.

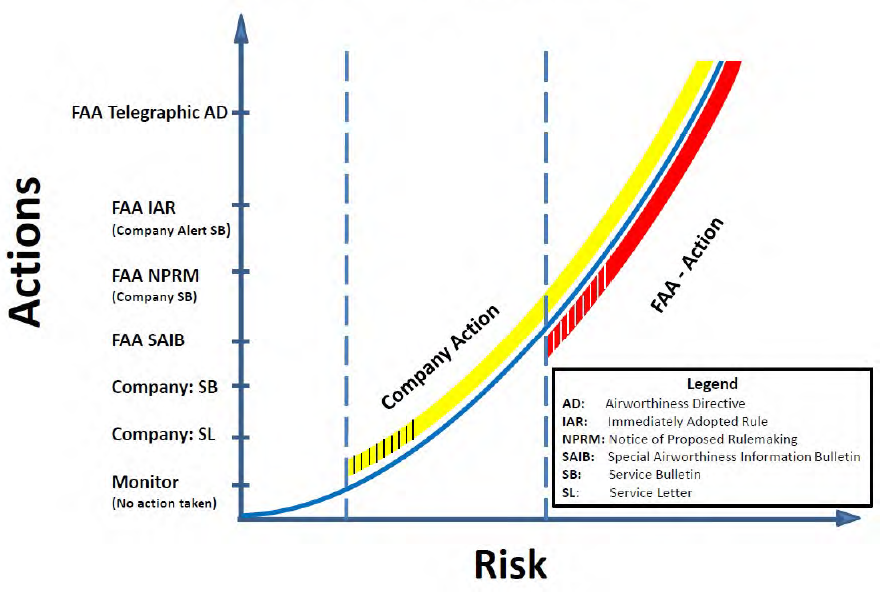

As described, the majority of accidents for aircraft are attributed to failings in Continued Airworthiness and Operations rather than design. We listed Continued Operational Safety, Operational Preparedness, and Service Readiness as the three important areas for Continued Airworthiness.

We dive into Continued Operational Safety first, specifically Safety Monitoring and Reporting.

Bjorn’s Corner: The challenges of airliner development. Part 24. Parallel Activities

October 8, 2021, ©. Leeham News: Last week, we described how we conduct the Certification Flight Test together with the Regulator.

Before we describe our path to completion of our flight test program, we need to pause for a minute and discuss some of the other parallel activities that need to come together prior to issues of Type Certificate and roll out of production aircraft.

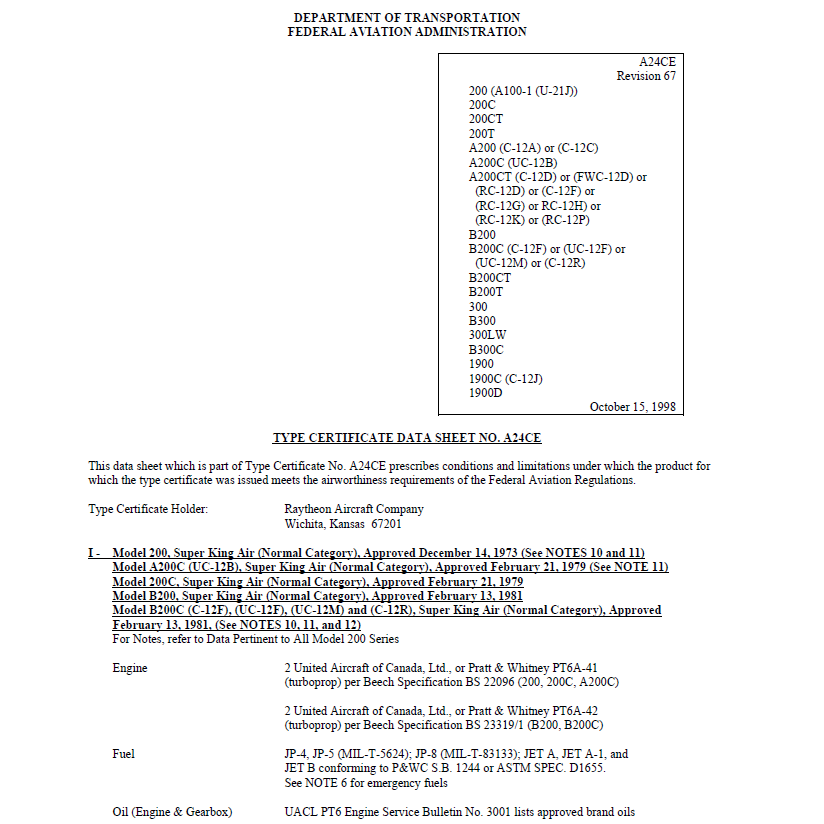

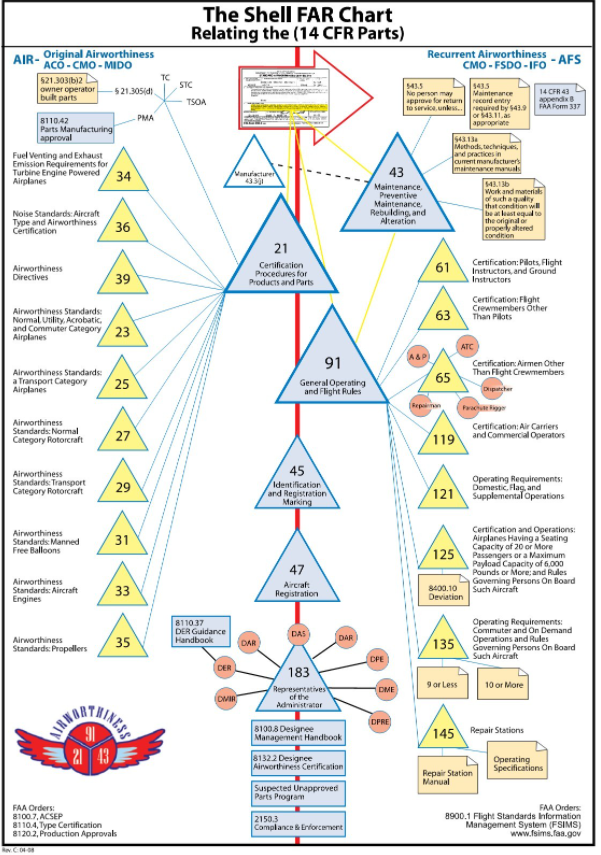

In article 3 you’ll recall we reviewed the breadth of regulatory involvement in aircraft development. While the work on the design and initial airworthiness (on the left in the chart below) is critical, it’s not the only set of rules we need to be working with if we want to achieve a successful Entry Into Service (EIS) of the aircraft.

In Part 21 of our series we already discussed the preparation of the production system. In the next few articles, we’ll be discussing three additional areas of work that we’re engaged in that must all come together at the program’s completion:

Bjorn’s Corner: The challenges of airliner development. Part 23. Certification Flight tests

October 1, 2021, ©. Leeham News: Last week, we described how we produced our Flight Test Articles, FTAs, and how the company flight tests are made.

Now we have finished the Company flight tests and made any modifications required to the FTAs so we can apply for Certification Flight tests with the regulator.

Bjorn’s Corner: The challenges of airliner development. Part 22. Flight tests

September 24, 2021, ©. Leeham News: Last week, we looked at the necessary Production Certificate for the production of our airplanes.

Now our program plan has approached the mid-phase of the Post-Launch phase. We start assembling our test aircraft to get to flight tests.

Bjorn’s Corner: The challenges of airliner development. Part 20. Production site and facilities

September 10, 2021, ©. Leeham News: Last week, we looked at the Rig design and manufacture for ground and flight testing.

We are now at the stage in our program (Figure 1) where we shall have scouted and deliberated over our Final Assembly production site (Violet bars). We now need to decide on the site and what facilities we need to build and/or hire.

Bjorn’s Corner: The challenges of airliner development. Part 19. Test rigs for ground and air use

September 3, 2021, ©. Leeham News: Last week, we looked at the Certification Compliance Planning we do concurrently with Detailed Design, Figure 1.

It’s now time for us to work on our Test rigs and systems for ground and flight testing. We need to get these defined before we freeze the aircraft’s configuration and start making our flight test aircraft.

Bjorn’s Corner: The challenges of airliner development. Part 18. Certification work after program launch.

August 27, 2021, ©. Leeham News: Last week, we started looking at our work during the Detailed Design phase after Product Launch. We outlined the exacting work needed to design all parts of the aircraft and how we must keep everything in sync.

An essential part of keeping everything in sync is the Certification Compliance Planning we do in this phase, Figure 1.